Safety

*Safety First: This is the message carried out by each employee in their hard hat and safety vest, but most importantly in their minds.

Roy Rock believes that no job or task is more important than protecting our workers’ health and safety. It is our policy and requirement that all employees recognize the value of practicing and adhering to our safety program. Our main safety program complies with all applicable standards and regulations of the Occupational Safety & Health Administration (OSHA). Also, we have several specific safety programs such as respiratory protection program, scaffold program, silica program, etc.

Roy Rock’s goal is zero incidents. The average number of our recordable accidents is significantly less than the average recordable accidents in the construction industry.

Safety is a core value at Roy Rock. We maintain an unwavering commitment to the safety of our people and trade partners through the implementation of our corporate safety program, detailed site-specific safety plans, extensive training, planning, and personal accountability. The commitment to a “zero-accident” safety culture includes not only our employees, but extends to all our subcontractors as well. The communication between our construction workers and the safety department, and the education that they receive through training are key in our organization. We motivate our workers and recognize them in every good safety habit they adopt while working in the field. While we can boast that we maintain a strong relationship with our workers because of the safety, what really excites us is sending our people home safely to their loved ones every day.

Safety meetings are held once a week on all of our projects.

Our commitment to safety was made a long time ago, and we are successful today because of the relentless efforts to improve every day.

Roy Rock maintains a comprehensive safety program. Our safety department includes a safety professional who is a certified OSHA outreach trainer. Safety is a commitment made by management, supervisors, foremen, construction assistants, construction workers, and every single employee working with us. We pride ourselves in creating a culture of safety by involving every worker in every safety protocol at the job site. We have created safety committees in each project, comprised of construction workers who have different functions. We consider every employee a member of the safety team.

The company offers several focused safety training classes for our construction workers throughout the year. They include training on some of the risks and exposures we face each day like scaffold erection, excavation, fall protection, load securement, rigging, means and methods of safe construction practices, etc. Individual classes are given by our safety professional. We also have relationships with first aid personnel, insurance representatives, and other safety professionals.

Tool box talks are also required to be held weekly. The topics are standardized, but job specifics are used accordingly.

The safety department is also in attendance at pre-construction meetings that include the Project Manager and other members of the project team. It is at this meeting that any questions regarding safety or any circumstances that are unique to the project are discussed and addressed.

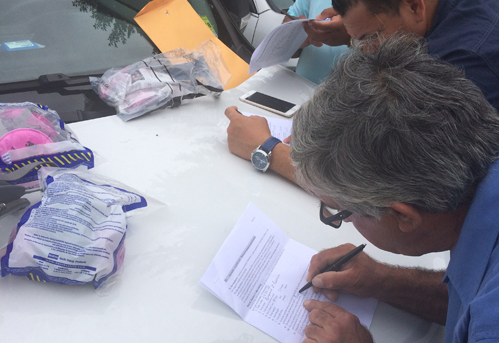

Roy Rock’s construction workers filling out medical papers before entering the Doctor’s office.

Roy Rock’s construction workers posing after Medical evaluations were carried out for the use of respirators to comply with the latest OSHA silica standards.

Just one of our in-house training sessions. This one was given for our scaffold erectors.

A Roy Rock worker wearing personal protective equipment that exceeds OSHA requirements.

A worker using our HEPA filter grinding machine and respirator. All of our equipment complies with the latest OSHA silica standards.

A Roy Rock worker cutting steel while wearing OSHA compliant safety glasses and face shield.

Roy Rock workers using a fall protection device. Another worker using a dust mask while chipping concrete.

Our Safety Program includes:

- Employee training & certifications

- Employee safety awards

- Monthly Management Safety Meetings

- Weekly Tool Box Talks

- Project specific Health and Safety Plans

- HAZWOPER 40 Certification

- Project specific Job Hazard Analysis

- Safety Checklists, Reports & Permits